New energy FPC dispensing machine

New energy FPC dispensing machine

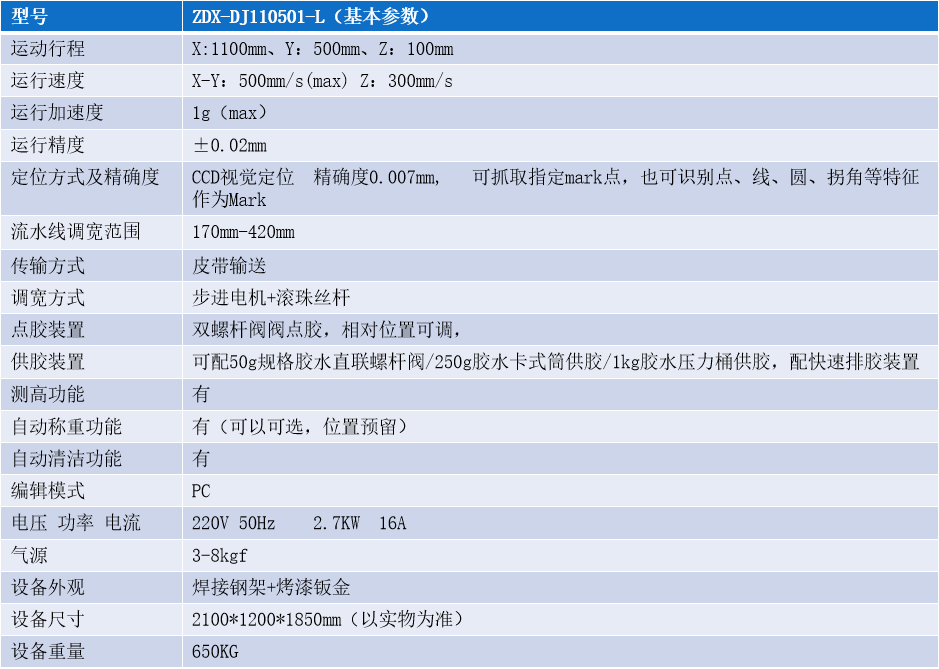

Introduction to New Energy FPC Gluing Machine - Equipment Module

New energy FPC dispensing machine (connector/NTC dispensing)

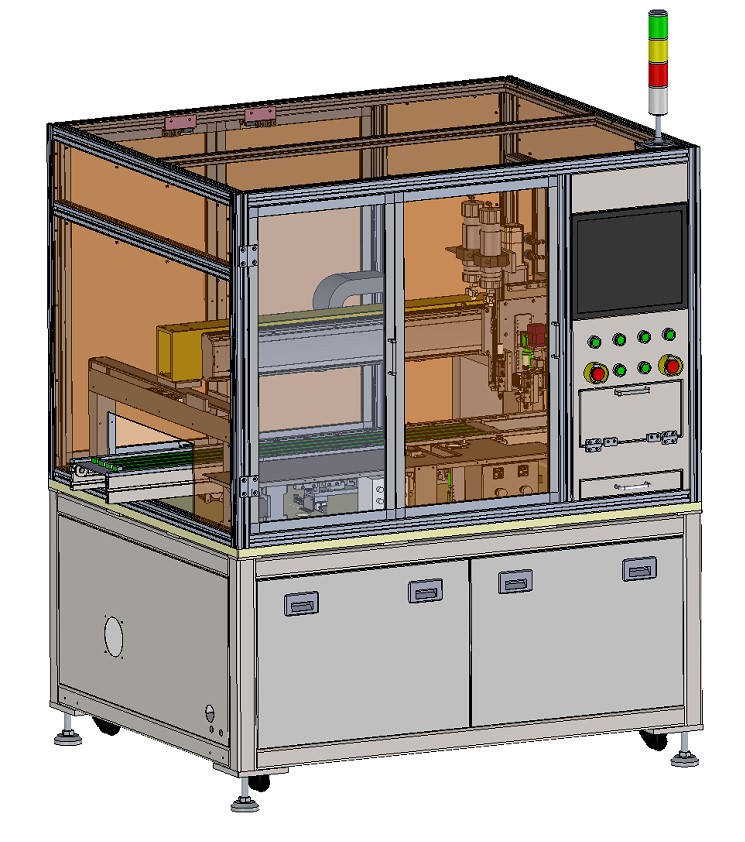

Equipment model: ZDX-DJ110501-L (for reference only, subject to actual conditions)

Equipment Overview:

1. Adopting a gantry three-axis mechanism, all of which are driven by servo motors and screw modules, with high stability and positioning accuracy;

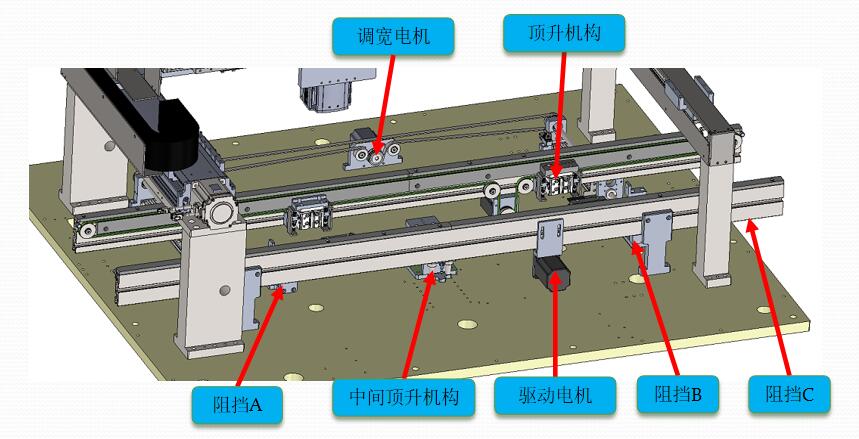

2. The automatic assembly line can be seamlessly connected with other equipment and is equipped with 3 sets of blocking mechanisms. Block A is a safety block, Block B is a first stage glue blocking, Block C is a second stage glue blocking, and a set of lifting mechanisms for glue dispensing off the track, resulting in higher flatness;

3. Double headed glue dispensing, one end fixed, and the other end automatically adjusted according to visual position;

4. It can control the air pressure, dispensing speed, and acceleration, and cooperate with the screw valve controller to control the dispensing amount;

5. Equipped with a weighing scale, regularly and regularly verifying the amount of glue dispensed, equipped with a glue wiping mechanism, automatically cleaning the nozzle to prevent residual glue from affecting the dispensing process.

Motor power and form:

X-axis: servo motor 400W; Double Y-axis: servo motor 400W (2 sets);

Z-axis: servo motor 400W (with brake);

Fine tune X-axis: Stepper motor 0.6N M. Fine tune Y-axis: Stepper motor 0.6N M,

Fine tune Z-axis: stepper motor 0.6N M;

Conveyor motor: stepper motor 2.3N M (2 sets)

Width adjustment motor: stepper motor 2.3N M

Basic parameters

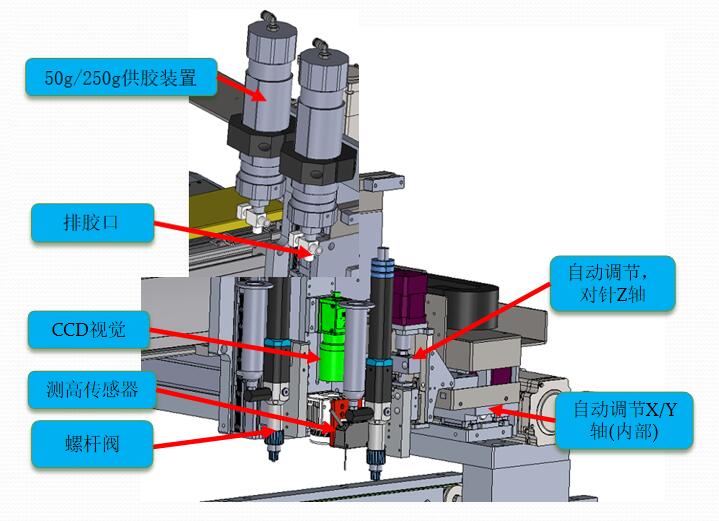

Connector/NTC dispensing device

Automatically adjust the X-axis range to ± 10mm, the Y-axis range to 0-100mm, and the relative positions of the two valves to 80-180mm; Adjust the Z-axis range of the needle to ± 5mm.

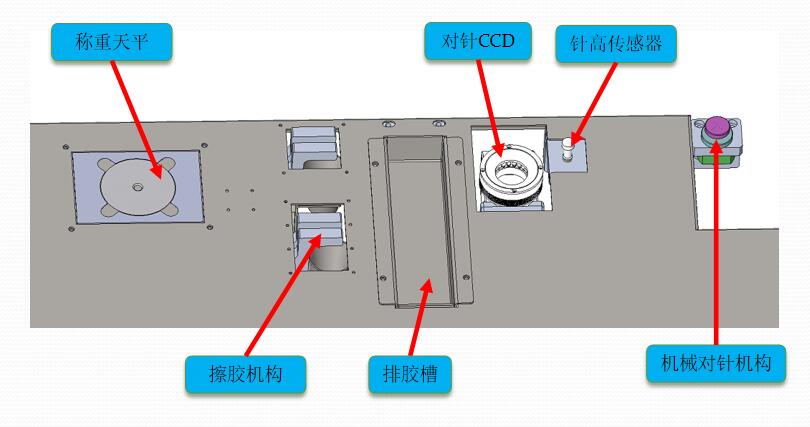

Connector and NTC adhesive weighing and needle alignment device

Rubber wiping mechanism: cylinder+sponge;

Weighing institution: weighing balance, with a range of 220g and an accuracy of 0.1mg;

Assembly line function: All dispensing machines have the same assembly line mode

The width of the assembly line is adjustable, with a range of 150-420mm. It is equipped with sensors to sense the position of the product and block it. The guide wheel and motor lift adjust the tension of the belt.