Side dispensing machine/visually guided edge dispensing

Side dispensing machine/visually guided edge dispensing

1、 Application scenarios

The side coating process is applied in the following scenarios:

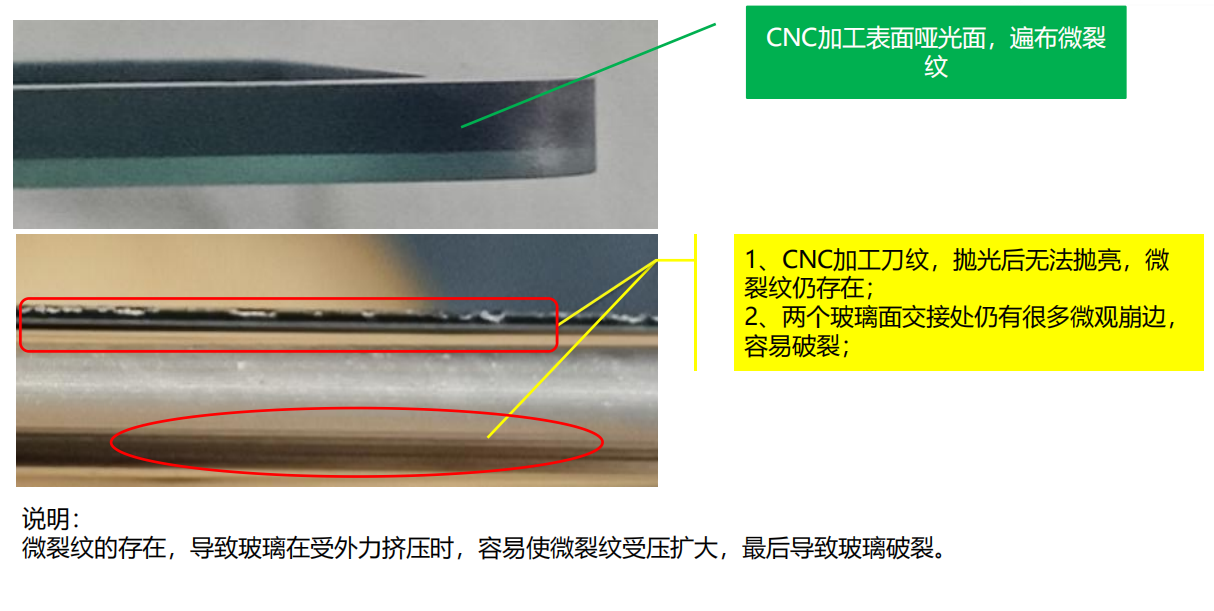

1. The glass CNC machining surface has a matte finish and is covered with microcracks (edge strengthening effect);

2 CNC machining of tool lines, unable to polish and micro cracks still exist (due to shading effect) after polishing;

3 After the Oled is adhered, the bright edge of the Cover Lens reflects light;

4 Mini Led/Micro LED edge ink protection;

It can effectively provide shading or three strong effects.

2、 Side gluing scheme

Fuqi Automation currently has two types of side gluing processes and has obtained certification from internationally renowned mobile phone manufacturers.

According to product specifications and size definitions, there are two options:

1. Automatic loading and unloading five axis dispensing solution (visual positioning+five axis dispensing)

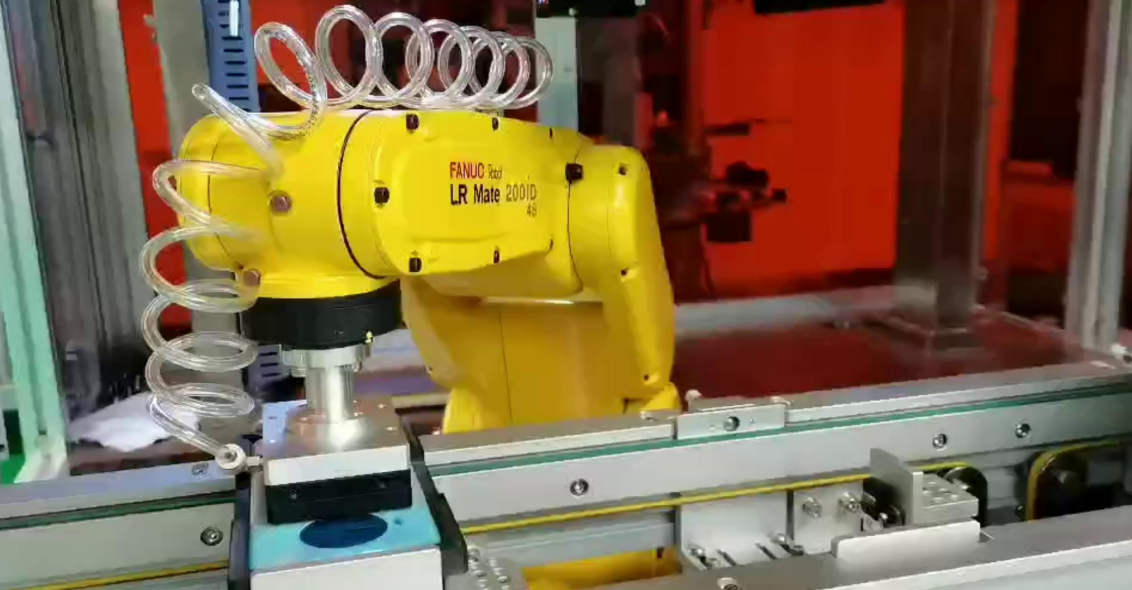

2. 3D trajectory guided robotic arm dispensing solution (laser line scanning+trajectory guidance)

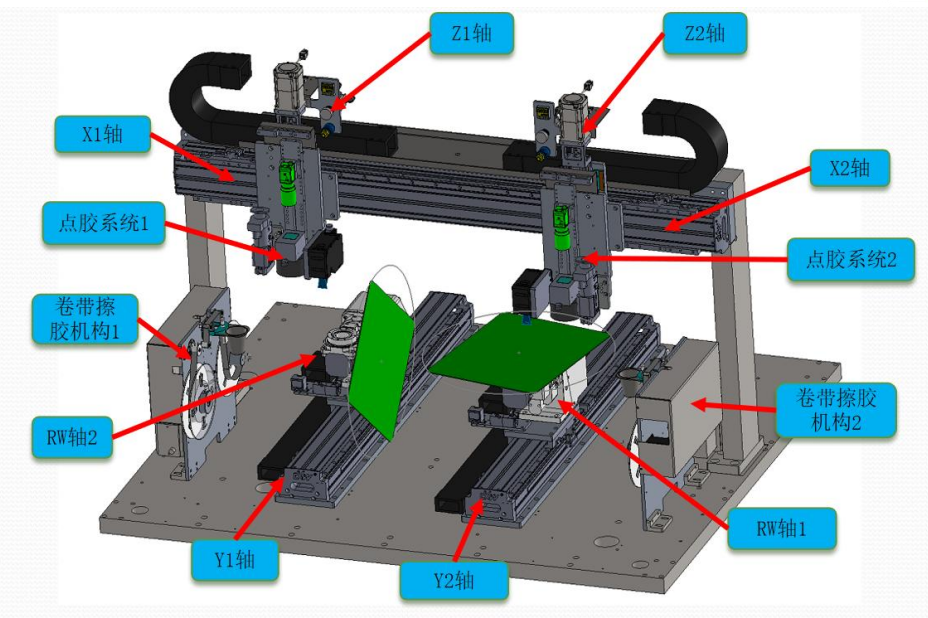

Scheme 1- Schematic diagram of the main mechanism for five axis dispensing

Automatic loading and unloading five axis dispensing solution (visual positioning+five axis dispensing)

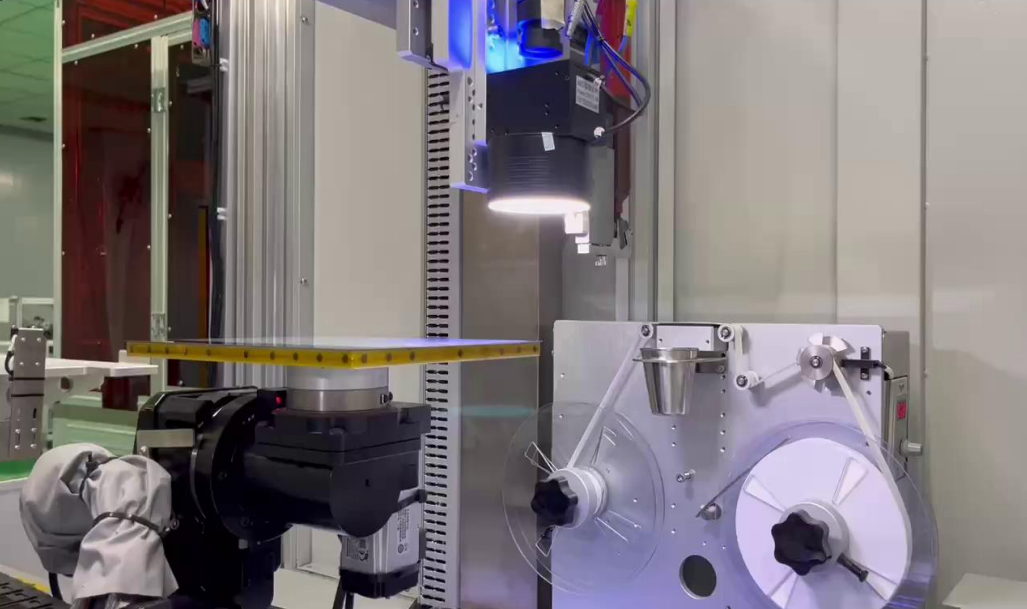

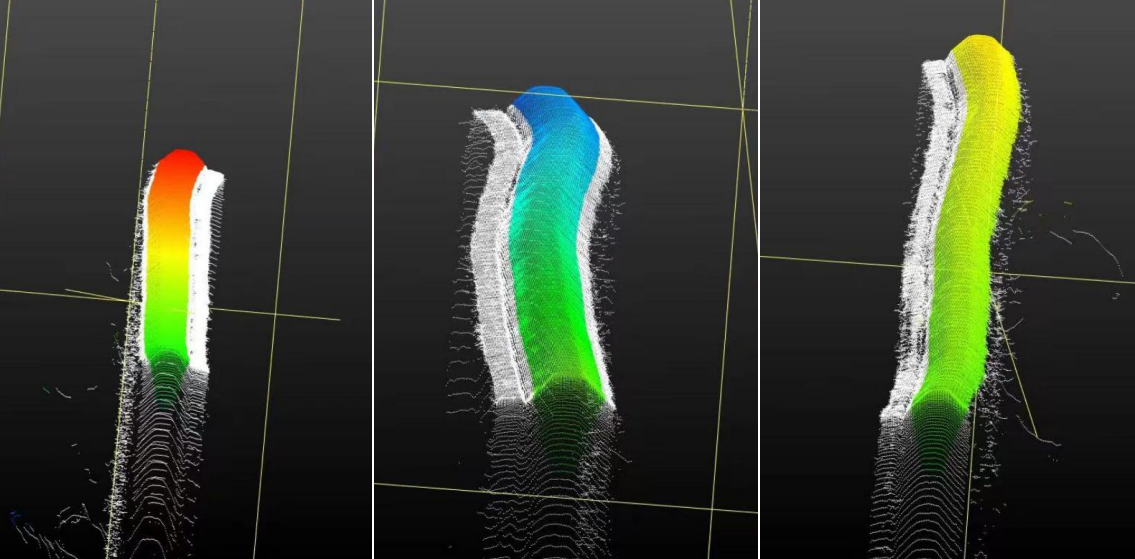

Option 2- Laser line scanning path

3D trajectory guided robotic arm dispensing solution (laser line scanning+trajectory guidance)

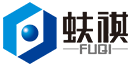

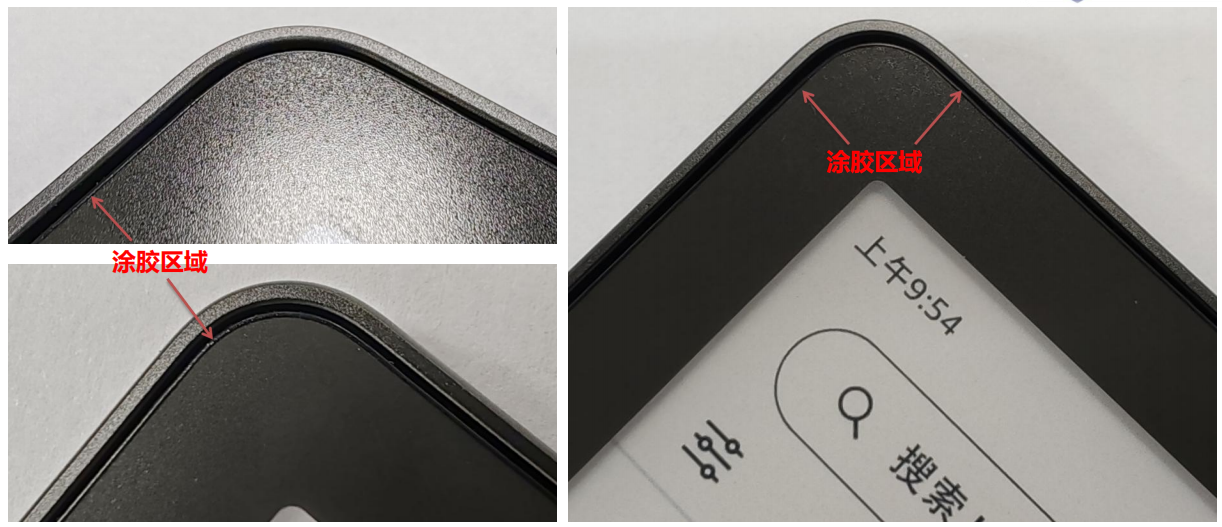

Effect - Water glue (spray valve)

Specification requirements: 1. The adhesive thickness is 0.25mm ± 0.05mm, and there should be no leakage or missing adhesive around it; 2. The starting point glue drop is ± 0.06mm; 3. Waves are not allowed on the edges;

Effect - Ink (Needle)

Specification requirements: 1. The ink thickness is 0.02mm ± 0.005mm, and there should be no ink leakage or shortage around the edges; Strict specifications: The ink should cover the front 0.05mm and the back should not overflow; 2. The starting point glue drop is ± 0.008mm;

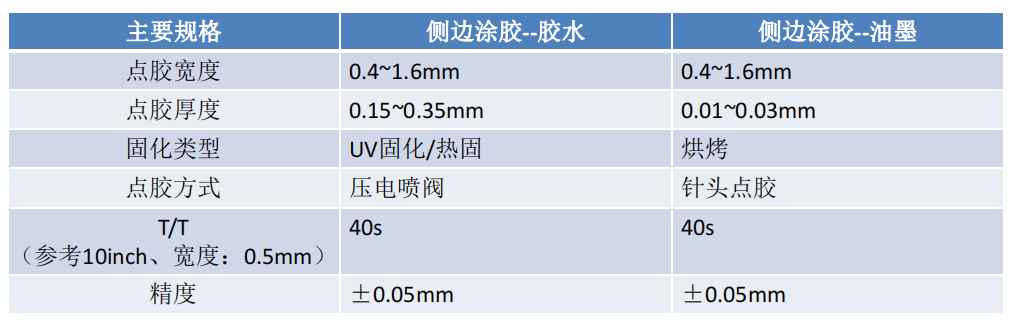

3、 Main specifications