New energy dispensing line/New energy FPC fully automatic dispensing and curing line

New energy dispensing line/New energy FPC fully automatic dispensing and curing line

New Energy Gluing Line/New Energy FPC Fully Automatic Gluing and Curing Line - Equipment Overview

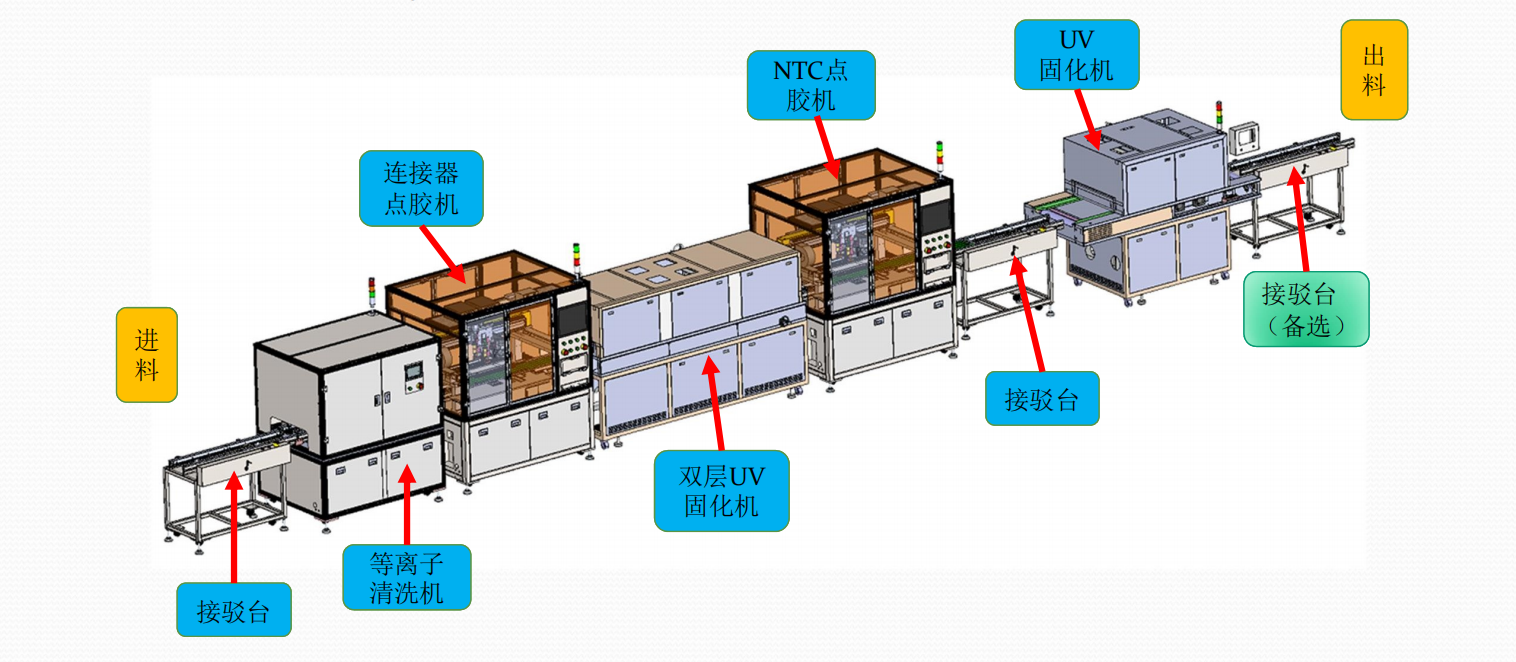

1.1 Complete Machine Description:

New energy FPC dispensing machine, this equipment is an automatic dispensing and curing line for new energy FPC; It is a series of functional equipment that integrates conveying, dispensing, tunnel furnace (customer provided) heat curing, etc. It has a high degree of automation and efficiency, and is equipped with 1-2 employees to take care of the entire line.

Model: ZDX-DJ-UV-1500

Preview of the fully automatic dispensing and curing line for new energy FPC

1.2 Equipment composition:

1.3 Overview of key points of the entire machine:

① All dispensing machines are double headed, increasing production capacity; Can independently complete position correction and asynchronous dispensing, avoiding dispensing failures caused by inaccurate employee materials;

② Each dispensing machine is equipped with a fast dispensing device, which reduces the waste of glue in the pipeline and saves dispensing time;

③ Each dispensing machine adopts CCD visual positioning and height measurement functions, with computer operation and programming, making it easy for employees to learn and understand;

④ The connector dispensing adopts screw valve dispensing, which has a large dispensing volume, fast speed, and high dispensing accuracy; NTC dispensing adopts a piezoelectric spray valve, which ensures accurate dispensing and reduces the generation of bubbles during the dispensing process;

⑤ The UV curing machine is equipped with real-time energy/temperature monitoring function, which alarms when it exceeds the set range and can retrieve equipment operation information (UV manufacturer);

⑥ The dispensing machine track can be automatically widened for convenience and speed, while the connecting platform and UV curing machine are manually widened;

⑦ The entire line is equipped with a plasma cleaning machine to clean the surface impurities of the product, remove impurities, foreign objects, etc;

⑧ The device data port is open and can be connected to MES. The dispensing machine has a QR code acquisition function.

1.4 Scope of applicable products for the equipment:

Size range of carrier plate: length 400-1800mm, width 170-420mm, thickness 2-5mm;

The products are arranged in a regular manner, and it is recommended to arrange them in even numbers. Double valve dispensing is recommended to ensure efficiency is not lost.

1.5 Glue dispensing accuracy:

Screw valve dispensing accuracy: ± 1%

Minimum dispensing volume: 0.005ml

Applicable adhesive viscosity: 1000-300000cps

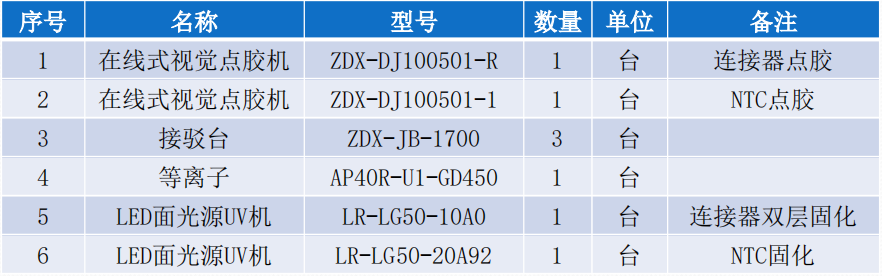

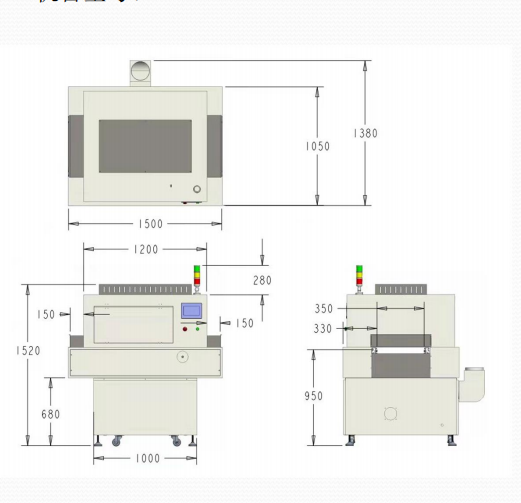

1.5. New Energy FPC Gluing Machine - Equipment Line Dimensional Drawing

Overall layout dimension diagram (based on the actual product)

Suggested equipment footprint size: reserve 1.5 meters of transfer space for each incoming and outgoing equipment, 1.2 meters for the front of the equipment, and 0.7 meters for the back. The total equipment footprint size is: (17+1.5+1.5) * (1.3+1.2+0.7)=20 * 3.2 (unit: meters) (excluding adding equipment size in the future)

2. Introduction to New Energy FPC Gluing Machine - Equipment Module

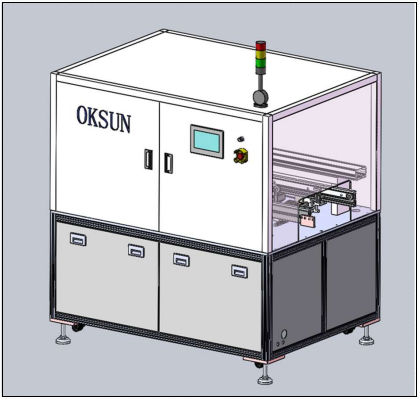

New energy FPC dispensing machine (connector/NTC dispensing)

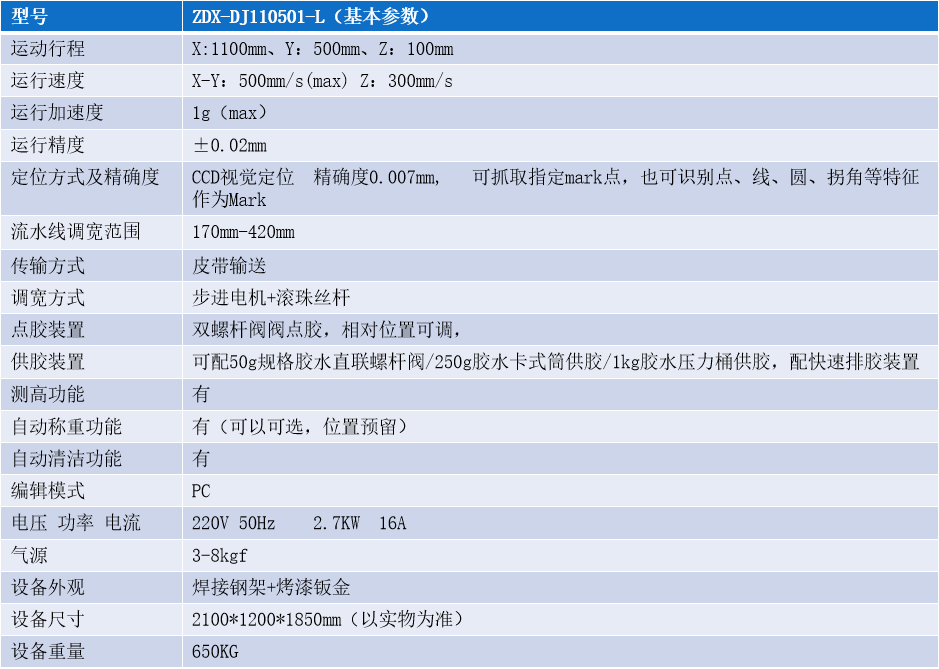

Equipment model: ZDX-DJ110501-L (for reference only, subject to actual conditions)

Equipment Overview:

1. Adopting a gantry three-axis mechanism, all of which are driven by servo motors and screw modules, with high stability and positioning accuracy;

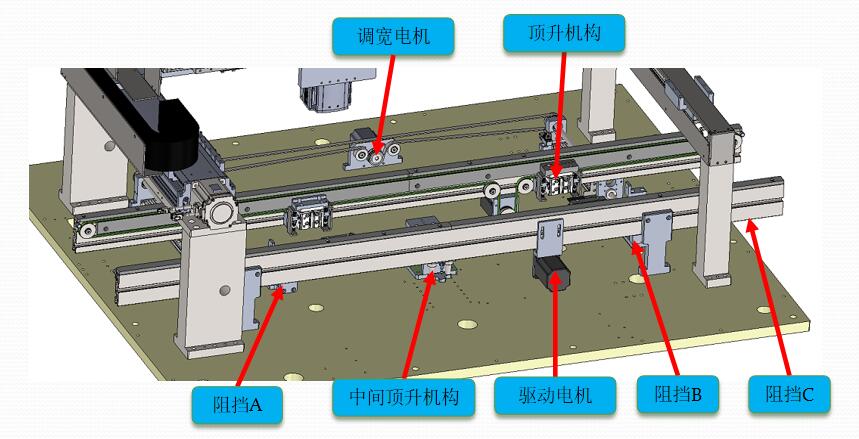

2. The automatic assembly line can be seamlessly connected with other equipment and is equipped with 3 sets of blocking mechanisms. Block A is a safety block, Block B is a first stage glue blocking, Block C is a second stage glue blocking, and a set of lifting mechanisms for glue dispensing off the track, resulting in higher flatness;

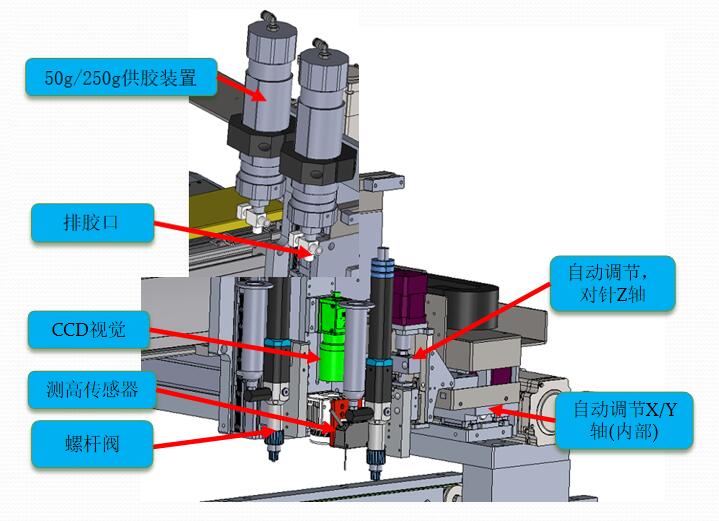

3. Double headed glue dispensing, one end fixed, and the other end automatically adjusted according to visual position;

4. It can control the air pressure, dispensing speed, and acceleration, and cooperate with the screw valve controller to control the dispensing amount;

5. Equipped with a weighing scale, regularly and regularly verifying the amount of glue dispensed, equipped with a glue wiping mechanism, automatically cleaning the nozzle to prevent residual glue from affecting the dispensing process.

Motor power and form:

X-axis: servo motor 400W; Double Y-axis: servo motor 400W (2 sets);

Z-axis: servo motor 400W (with brake);

Fine tune X-axis: Stepper motor 0.6N M, Fine tune Y-axis: Stepper motor 0.6N M,

Fine tune Z-axis: stepper motor 0.6N M;

Conveyor motor: stepper motor 2.3N M (2 sets)

Width adjustment motor: stepper motor 2.3N M

Basic parameters

Connector/NTC dispensing device

Automatically adjust the X-axis range to ± 10mm, the Y-axis range to 0-100mm, and the relative positions of the two valves to 80-180mm; Adjust the Z-axis range of the needle to ± 5mm.

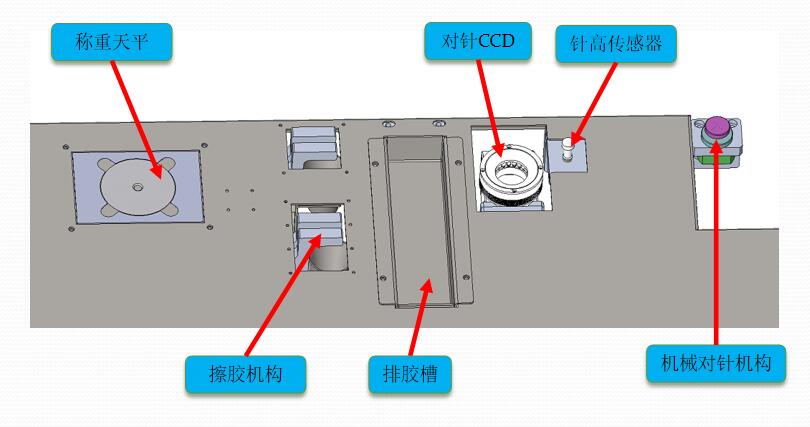

Connector and NTC adhesive weighing and needle alignment device

Rubber wiping mechanism: cylinder+sponge;

Weighing institution: weighing balance, with a range of 220g and an accuracy of 0.1mg;

Assembly line function: All dispensing machines have the same assembly line mode

The width of the assembly line is adjustable, with a range of 150-420mm. It is equipped with sensors to sense the position of the product and block it. The guide wheel and motor lift adjust the tension of the belt.

3. Docking station equipment model: ZDX-JB-1700

Equipment Overview: This device is a product loading and transportation platform, equipped with feeding, receiving, and discharging sensors, and is an auxiliary device for connecting upstream and downstream equipment. Manual width adjustment range of the assembly line 100-450mm dust cover (customer optional) Motor power and form: Conveyor motor: Stepper motor 2.3N M (2 sets)

4. Mobile Docking Station Equipment Model: ZDX-YDJB-1700

Equipment Overview: This equipment is a product loading plate transfer transportation platform, equipped with feeding, receiving, and discharging sensors, and auxiliary equipment for connecting upstream and downstream equipment. The conveying line frame is above the moving axis and can connect to lines that are not in the same straight line. The manual width adjustment range of the assembly line is 100-450mm; Mobile travel: 550mm dust cover (customer optional)

5. Plasma cleaning machine equipment model: AP40R-U1-GD450

Equipment Overview: 1. This equipment is a track type plasma surface cleaning equipment, with an adjustable track width of 150-450mm; Applicable products: 300-1500mm; 2. Intelligent human-machine engineering system: parameter adjustment through screen; And can save hundreds of sets of parameters. 3. Use the XYZ three-axis module to drive one plasma jet rotating spray gun for processing, with a module stroke of 1800 * 450 * 100mm. 4. The rated power of the plasma power supply is 1000W; Use power of 400-600W. The plasma jet power is visually intuitive. Effectively handle heights of 10-20mm. 5. Transmission speed 1-5 meters/minute, adjustable It has sound and light alarms and emergency stop functions in case of abnormal or faulty operation. 7. The equipment has incoming material sensing function; It can operate independently or in series. 8. Software permissions are designed with a three-level hierarchy, supporting different permissions for different roles.

6. Cooling cache machine equipment model: ZDX-LQHC-2300

Equipment Overview: This equipment is a product loading plate transfer transportation platform, equipped with feeding, receiving, and discharging sensors, and auxiliary equipment for connecting upstream and downstream equipment. The conveying line frame is above the moving axis and can connect to lines that are not in the same straight line. The manual width adjustment range of the assembly line is 150-450mm; Maximum number of boards that can be stored: 15 pieces. Motor power and form: conveyor line motor: stepper motor 2.3N M (2 sets) width adjustment motor: stepper motor 4.5N M; Lift shaft motor: stepper motor 4.5N M (2 sets)

7. UV curing furnace

① The UV light source adopts a high-power density LED surface light source, using imported UVLED chips to ensure long-term stability;

② LED cold light source, combined with high-power fan cooling, can ensure a sufficiently low curing temperature;

③ The LED light source adopts a UVA wavelength of 405 ± 5nm as the main wavelength, which can ensure good curing effect of the UV adhesive;

④ Each set of UV light source system is independently controlled, with adjustable number of light sources and infinite adjustment of light power to meet different process requirements. The position of the UV lamp can be adjusted according to needs, and there is a roller type adjustment above the equipment, with an adjustable range of 0-200mm;

⑤ After the product enters the upper track, the positioning cylinder rises. When the product reaches its position, the track stops running and the light source starts to work and light up. Set the lighting time accordingly; The track rises, and after the product enters the upper track, the positioning cylinder rises. When the product reaches its position, the track stops running and the light source starts working and lighting up. After setting the lighting time, the track descends. After the upper layer is solidified, the cylinder descends and the track starts running. The product is discharged first and then fed, and then switched to the lower layer;

⑥ A comprehensive monitoring and control system independently developed: LED monitoring, temperature monitoring, over temperature alarm, power supply monitoring; Ensure that the system is in the optimal operating state, configure an energy monitoring sensor under the light source, and monitor the intensity and accumulated illuminance of the illuminated energy in real-time every time it is lit. Set the energy range through software, and both low and high energy levels will sound an alarm;

⑦ PLC human-machine interface, convenient operation and process monitoring

The LR-LG50-20A92 UVLED curing furnace is used for UV adhesive curing in the automotive electronics industry The basic information of the equipment consists of six parts: light source, cooling system, power supply system, transmission system, shading system, control system, etc. The light source adopts imported 395nm wavelength high-power density UVLED cold light source, with a power of 10-100% stepless adjustment; The cooling system adopts air-cooled heat dissipation method; The furnace is equipped with a high-power fan to cool down the temperature inside, ensuring that the surface of the product has a sufficiently low temperature. The shading system uses insulation and anti UV materials, and a shading mechanism is installed at the loading and unloading positions to block UV light and avoid harm to human health; The control system adopts PLC and touch screen HMI control, and is equipped with a comprehensive monitoring system;