What is a new energy dispensing line/new energy FPC fully automatic dispensing and curing line?

The new energy dispensing line is a new energy FPC fully automatic dispensing and curing line under the Fuqi Automation dispensing series equipment. Below, we will have a specific understanding from the following points.

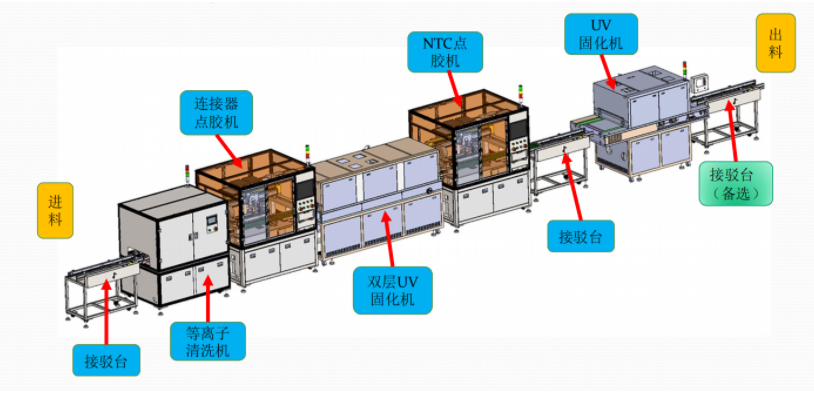

1、 Complete machine description

The new energy dispensing machine, also known as the new energy FPC fully automatic dispensing and curing line, is a series of functional equipment that integrates conveying, dispensing, tunnel furnace (customer provided) thermal curing, etc. It has a high degree of automation and efficiency, and is equipped with 1-2 employees to take care of the entire line.

Model: ZDX-DJ-UV-1500

Preview of the fully automatic dispensing and curing line for new energy FPC

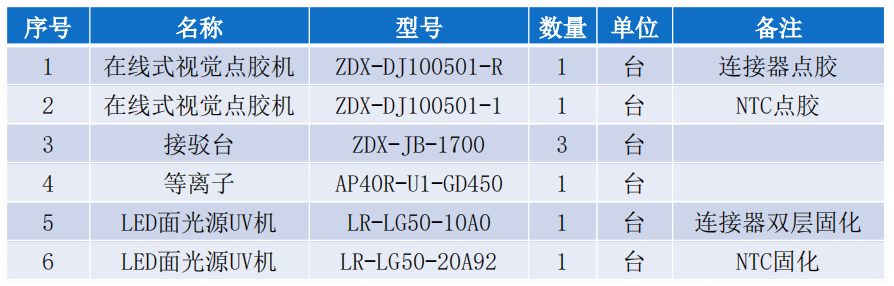

2、 Equipment composition

3、 Overview of Key Points of the Whole Machine

① All dispensing machines are double headed, increasing production capacity; Can independently complete position correction and asynchronous dispensing, avoiding dispensing failures caused by inaccurate employee materials;

② Each dispensing machine is equipped with a fast dispensing device, which reduces the waste of glue in the pipeline and saves dispensing time;

③ Each dispensing machine adopts CCD visual positioning and height measurement functions, with computer operation and programming, making it easy for employees to learn and understand;

④ The connector dispensing adopts screw valve dispensing, which has a large dispensing volume, fast speed, and high dispensing accuracy; NTC dispensing adopts a piezoelectric spray valve, which ensures accurate dispensing and reduces the generation of bubbles during the dispensing process;

⑤ The UV curing machine is equipped with real-time energy/temperature monitoring function, which alarms when it exceeds the set range and can retrieve equipment operation information (UV manufacturer);

⑥ The dispensing machine track can be automatically widened for convenience and speed, while the connecting platform and UV curing machine are manually widened;

⑦ The entire line is equipped with a plasma cleaning machine to clean the surface impurities of the product, remove impurities, foreign objects, etc;

⑧ The device data port is open and can be connected to MES. The dispensing machine has a QR code acquisition function.

4、 Applicable product range of the equipment

Size range of carrier plate: length 400-1800mm, width 170-420mm, thickness 2-5mm;

The products are arranged in a regular manner, and it is recommended to arrange them in even numbers. Double valve dispensing is recommended to ensure efficiency is not lost.

5、 Glue dispensing accuracy

Screw valve dispensing accuracy: ± 1%

Minimum dispensing volume: 0.005ml

Applicable adhesive viscosity: 1000-300000cps