More and more manual tasks are being replaced by automated equipment

International freight forwarding companies need to collect data information on customer goods in their daily logistics operations, including length, width, height, volume, weight, and barcode information. Traditional methods involve manually collecting data one by one. However, with the evolution of logistics skills, many companies gradually choose automated data collection equipment.

Traditional manual homework not only requires a lot of manual labor, but also consumes a lot of time, resulting in inaccurate data acquisition and simple presentation of data disorder, which are significant drawbacks; Through automated data collection equipment, high-precision measuring lenses, scanning cameras, and weighing equipment, various information of goods can be quickly and accurately obtained. The data can be directly connected to the customer's ERP system, completing more workload at the same time, assisting enterprises in reducing costs and improving economic benefits. So, manual work is increasingly being replaced by automated equipment.

Below, we will introduce several automation equipment of Xiamen Fuqi Automation Equipment Co., Ltd

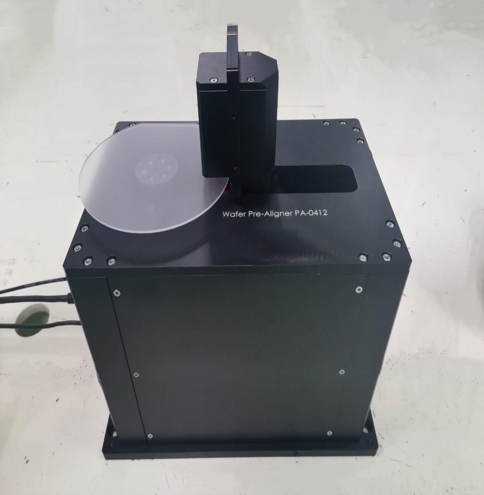

Pre aligner: Chinese name: wafer pre positioning system/wafer calibrator. This device achieves high-precision and efficient pre positioning of the center and flat edges (notches) of 4-12 inch wafer wafers, serving the transportation and handling needs of wafer wafers.

Load Port: Chinese name: Wafer Loading and Unloading Machine/Wafer Loading Machine, installed in front of EFEM * (Equipment Front End Module), used as a window for wafer entry and exit of EFEM. The Load Port is installed in front of the EFEM * (Equipment Front End Module) and serves as a window for wafers to enter and exit the EFEM; Intelligent and flexible factory interface modules for tool automation; Supporting excellent reliability and ultra clean performance; Maximizing interoperability, seamless interchangeability, and ease of configuration; Compatible with all FOUP and automatic front open shipping boxes (FOSB) delivered manually or through AMHS vehicles that comply with SEMI requirements; Used to maintain the cleanliness of the wafer during transportation.

FL4310 multifunctional vertical dispensing machine: The FL series desktop dispensing machine is meticulously designed with years of dispensing experience, focusing on details and user experience. This device has a mature software control system, which can be produced on a single machine or added with upper and lower boards, and can be used in the assembly line for automatic feeding and unloading.